What is meant by Control of Work (COW)?

Control of Work (COW) is a management tool that is used in collaboration with other management safety system or systems of work within an organization, in order to keep the workplace safe. ‘Safe’ in this case, is taken to mean: – without accident or injury to people, damage to equipment or unwarranted release of hydrocarbons to the environment. COW ensures that administrative controls are established.

What are the Objectives of COW?

- To reduce the workforce from exposed risk and the potential for harm to others

- To ensure that the HSSE Policy Statement Commitment complies with regulatory requirements; OSH Act, MEEI, EMA, MOWT

- To provide a consistent approach to a safe systems of work.

- To focus on the safe execution of workplace activities or Risk Control measures.

- To manage changes and associated risks in the workplace. Eg. Self- verification Audits and Pre-inspection checks.

COW Improved (PTW) System

- A Permit to Work System (PTWS) is a standard operation procedure used to issue documented permission to perform tasks that are considered hazardous or non-routine.

- A PTWS form consists of specific instructions of the nature of the job, the time and place along with adequate information of critical safety procedures to follow, to help prevent accident or injury to personnel, damage to plant/machinery and environmental protection. It is also a means of communication between the Site Management Authority, Supervisors, Operators, and those who carry out the work.

COW Main Types of Work Permits

- Hot Work Certificate

- Cold Work Permit

- Height Work Permit

- Confined Space Entry Work Permit

- Excavation Certificate

- Chemical Work Permit

- Electrical Isolation Certificate

- Mechanical Isolation Certificate

- Lifting Works Certificate

How the PTWS aims to assist COW

The PTWS aims to ensure that proper planning and precautions are taken with hazards to control the risk of a particular job/task. A Permit to Work System:

- Authorizes certain persons to carry out specific work at certain times and places.

- Identifies all the risks and hazards associated with the task/job.

- Sets out the precautions and mitigation measures needed complete the work safely.

- Ensures the Site Management/Authority is aware of the ongoing activities in their area as well as approving same to be used.

- Ensures the right people and equipment are onsite and/or onboard to conduct the specific requested task/job.

Conclusion

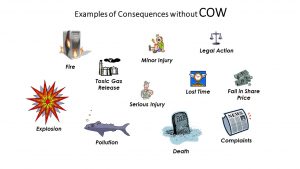

- Full implementation of a Control of Work program would be beneficial to the organization in the following ways as displayed below:

- All members of staff (inclusive of contractors) would be highly motivated and proactive which would greatly assist with the reduction of accidents and incidents.

2 Comments.

Is this a paperless PTW System

It depends on the organization, but PTW can be paperless if one desires.